Bonded Burnishers: Stress Relief by Peenburnishing

Bonded Burnishers™ also relieve stress – now achieved by flap peening, ultrasonic peening, and tools such as the 3M™ Roto Peen Flap Assembly™ – by compressing surface material into the metal mass.

The video below shows an Almen strip type parcel held in a steel support being treated with a Peenburnisher™ perpendicular to the strip’s length.

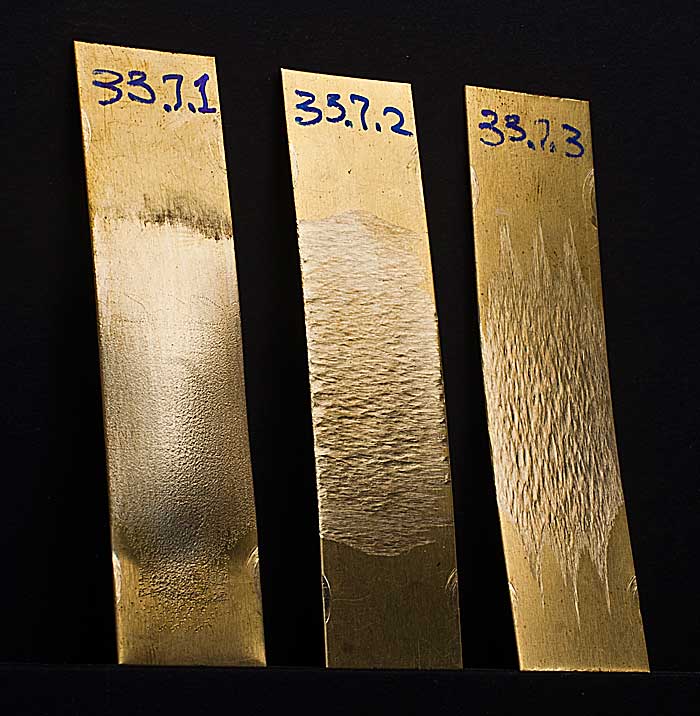

The following image shows the comparative results on Almen-type strips of Peenburnishing™ and 3M Roto Peen™ tooling.

The left strip shows the results of flap peening with a 3MRoto Peen Flap Assembly TC330™; the pillow form of the worked area shows that the internal structure of the strip subsurface has been put into compression equally in all directions.

The center strip shows the results of Peenburnishing™ perpendicular to the length of the strip.

The strip on the right shows the results of Peenburnishing™ parallel to the length of the strip.

Summary: The concave and convex arches of the Peenburnished™ strips demonstrate that stress relief through production of compression within the metal body can be selectively controlled.

Furthermore, the amount of force applied by the tool against the workpiece surface is dramatically enhanced with Peenburnishing™ compared to the Roto Peen™ tool, resulting in more efficient, more selective control of the peening process.