Bonded Burnishing Anti-Abrasive Technology ™

Sigma Surfacing presents………

Bonded Burnishing™: A Patent-Pending System for a New Class of Tools

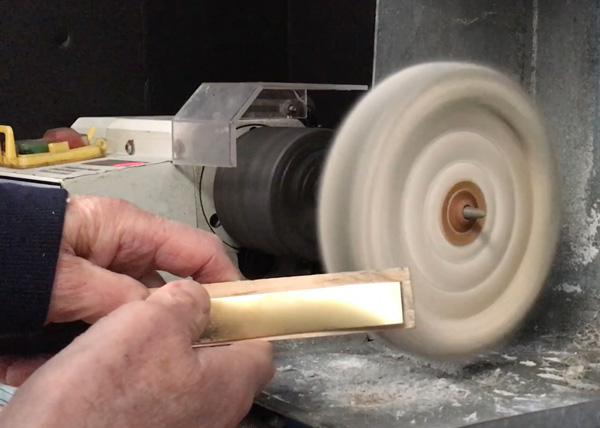

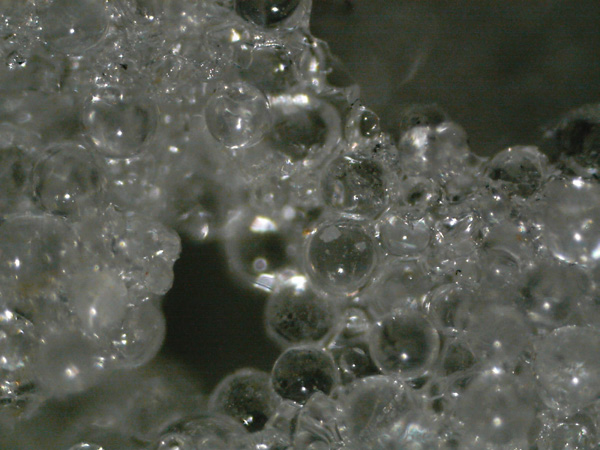

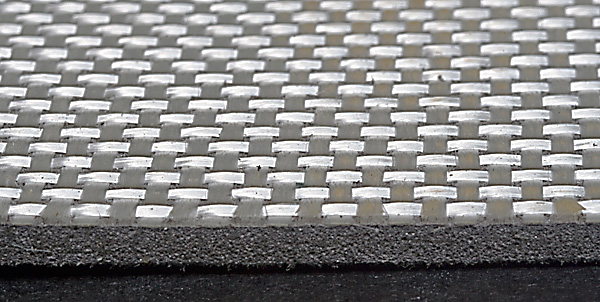

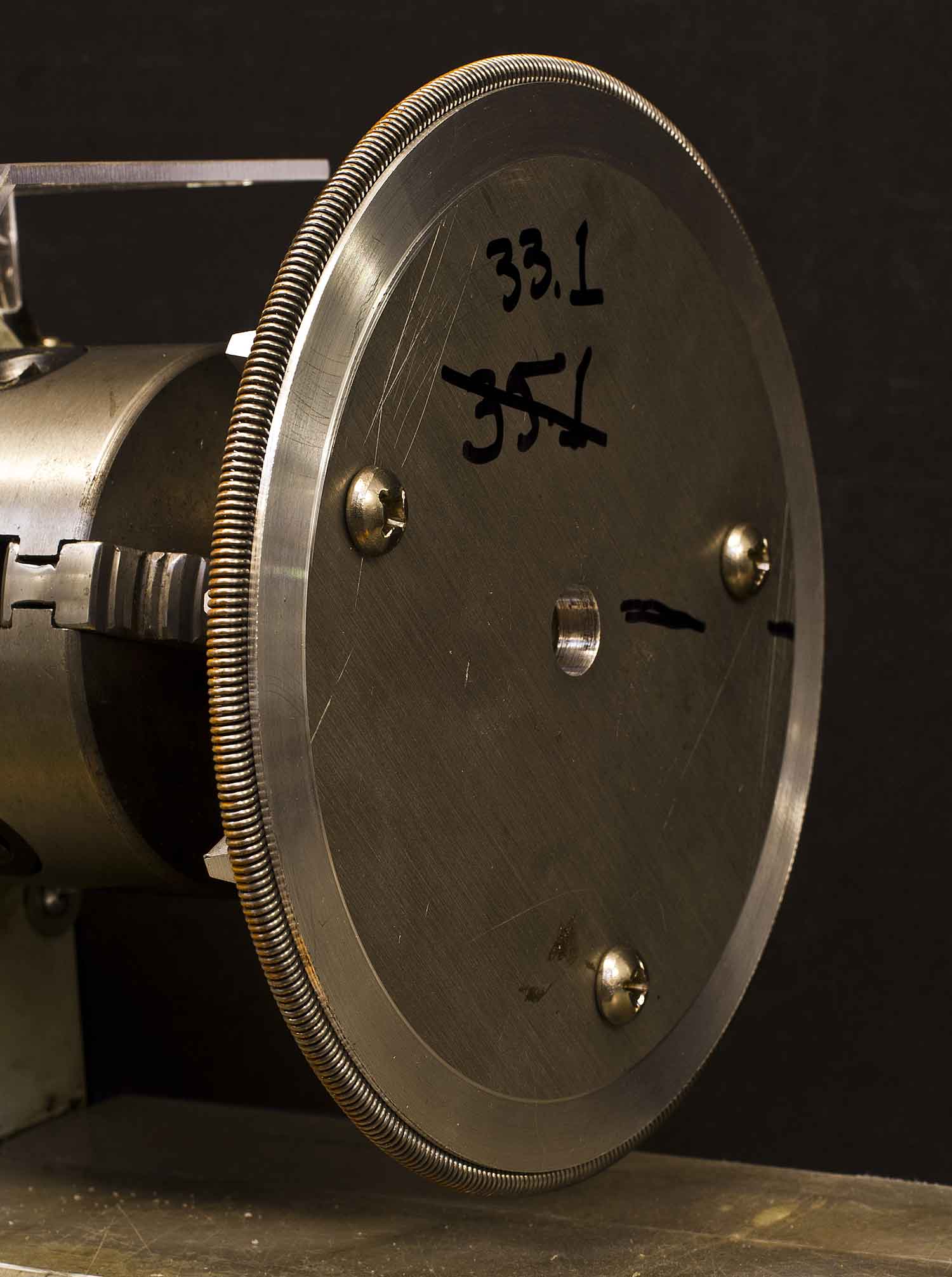

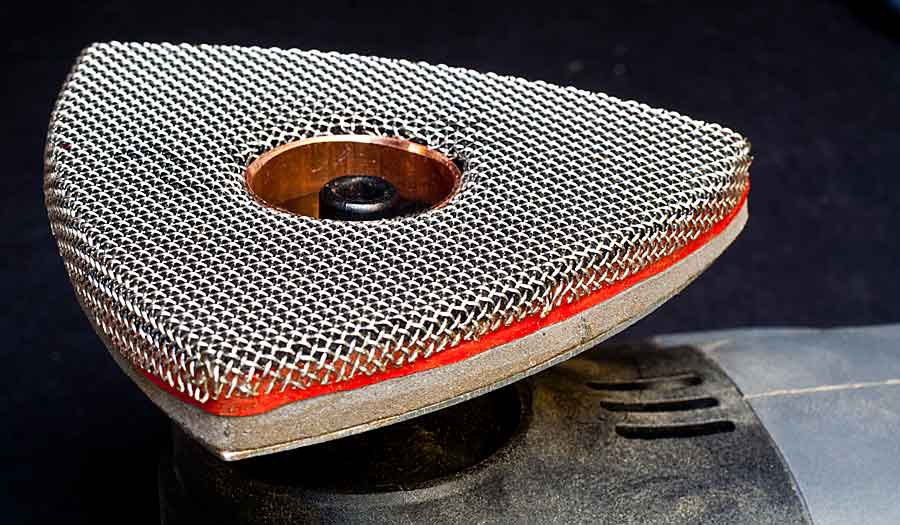

Bonded Burnishing™ isn’t just a process done by a tool. Bonded Burnishing™ is an entirely new system for modifying surfaces by burnishing, peening and adherence with Bonded Burnisher Anti-Abrasive Tools™. The new class of surfacing tools don’t don’t cut material away from a surface with ever finer sharp grains. Instead, the new tools use a simple new concept; improving surfaces by the use of multiple mini-burnishers in the form of fibers and spheroids that are bonded onto – or into – a ground, such as paper, fabric, foams, and solid masses such as wheels and blocks. Many of the tools are producible with the same machinery now used for abrasives, the difference being the replacement of sharp, abrasive, cutting grains with smooth spheroids and fibers.

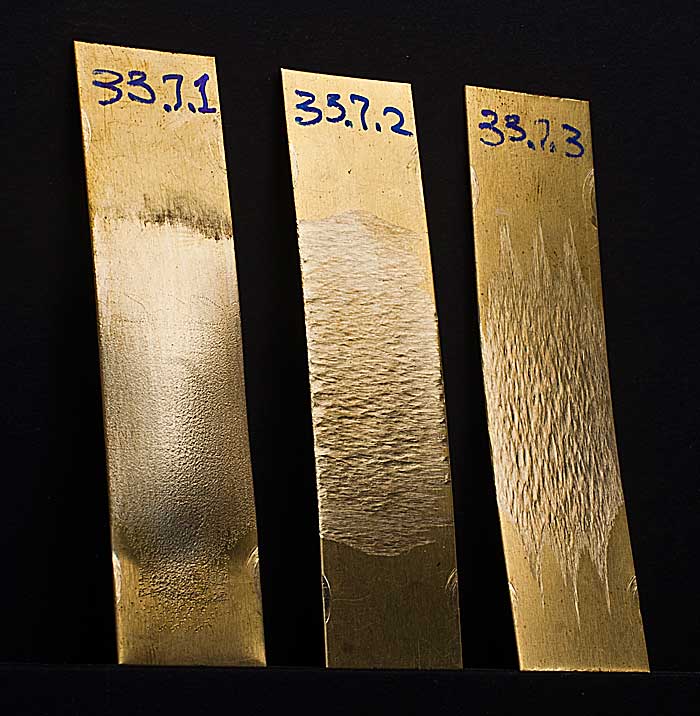

The new system results in tools that accomplish their work by three related processes: They move material across a surface: They compress the material: They may selectively remove controlled amounts of material by adhesion, that is, by dragging material away from the surface. All three processes generate little or no waste compared to abrasive tools.

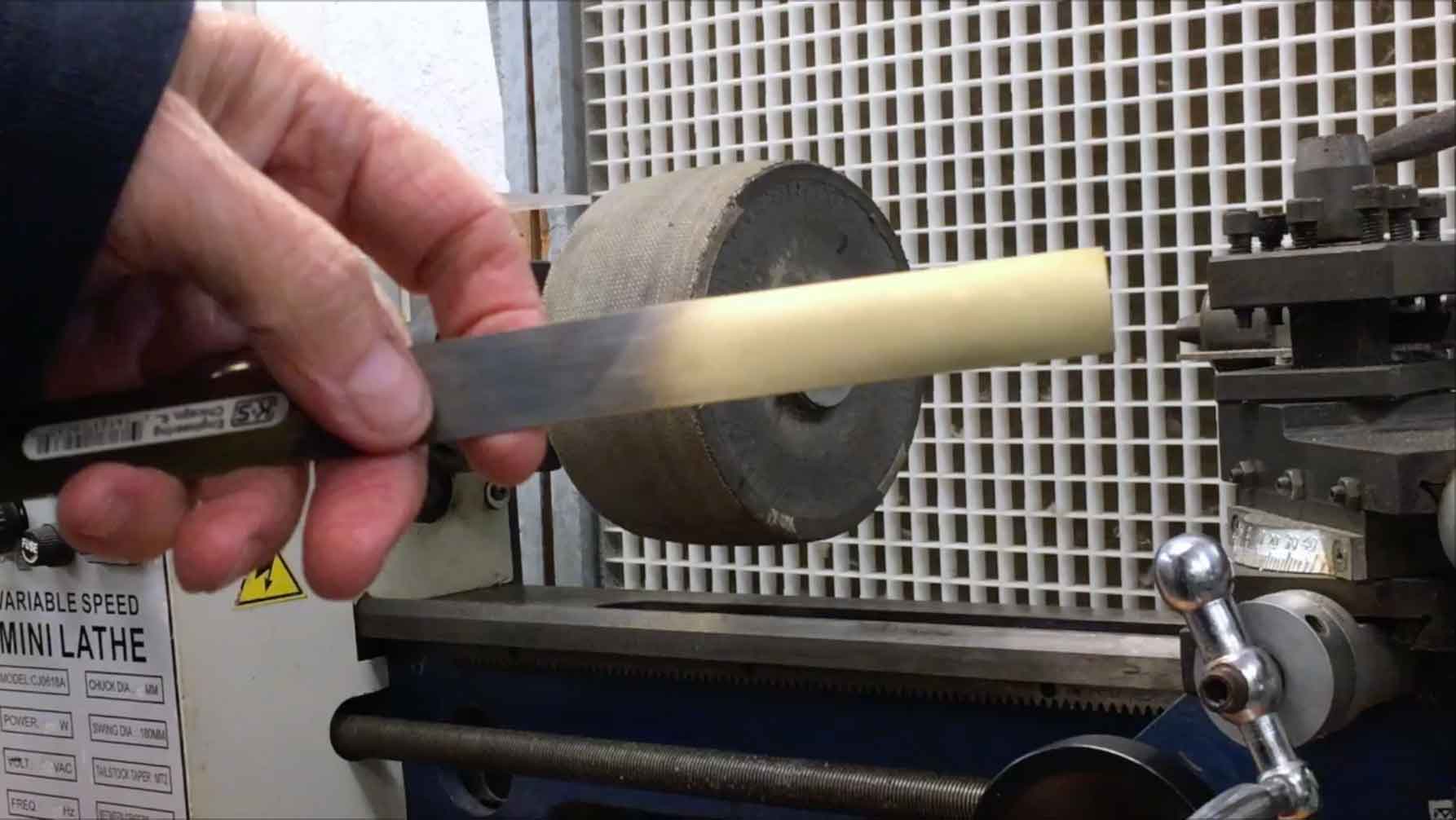

Click on the images below to see a selection of our Bonded Burnisher™ tool prototypes.

By using Bonded Burnishing Anti-Abrasives™, safety issues inherent in present finishing processes – high tool speed, noise, dust generation and high energy use – are dramatically reduced.

Bonded Burnisher tools™ operate at a wide variety of speeds, often dramatically lower than the speeds of polishing lathes and grinders now commonly used resulting in improved surface quality, lower energy costs, dramatically reduced recycling and tooling costs, and a quieter, brighter, cleaner and more productive work environment.